Hydrogen is like a Swiss army knife: it can be used for a hundred and one applications. But there is a catch, because emission-free ‘green’ hydrogen will become a scarce commodity in the coming decades. Therefore, the transition to a sustainable, climate-friendly global economy will only be possible if we use hydrogen wisely.

Hydrogen is the prima donna of the periodic table of the elements. It is the lightest element, but at the same time – especially in terms of application – it is one of the most unique. Indeed, in pure molecular form (H2) it can be used for anything and everything. From the generation of electricity and powering cars, ships and aircraft, to the heating of buildings and the production of steel, to the manufacture of fertilisers, ammonia and other chemicals.

Unfortunately, pure hydrogen is very rare on earth. That means it needs to be extracted with energy from fossil raw materials such as natural gas, through a process called steam reforming, or from water through electrolysis. Almost all hydrogen is currently produced using the first method, releasing as much as 9 kilograms of CO2 per kilogram of hydrogen. Needless to say, producing this so-called grey hydrogen is anything but climate-friendly.

That means the second method, electrolysis, has much more potential, also because this method of producing hydrogen offers comparable efficiency to steam reforming. But then the electricity used to split water into hydrogen and oxygen has to be as low-carbon as possible. Only then can we truly talk of ‘green’ hydrogen. Meeting this condition is much more difficult than it may seem. To green all hydrogen production in the world today, an electricity generation equivalent to 25% of total world electricity generation would be necessary. And all of this must be carbon-neutral energy, for example from renewable sources such as solar and wind or from hydropower. It is clear that this green energy does not exist today and will not exist in the near future – on the contrary, new ‘green’ capacity will be used as much as possible to electrify the economy.

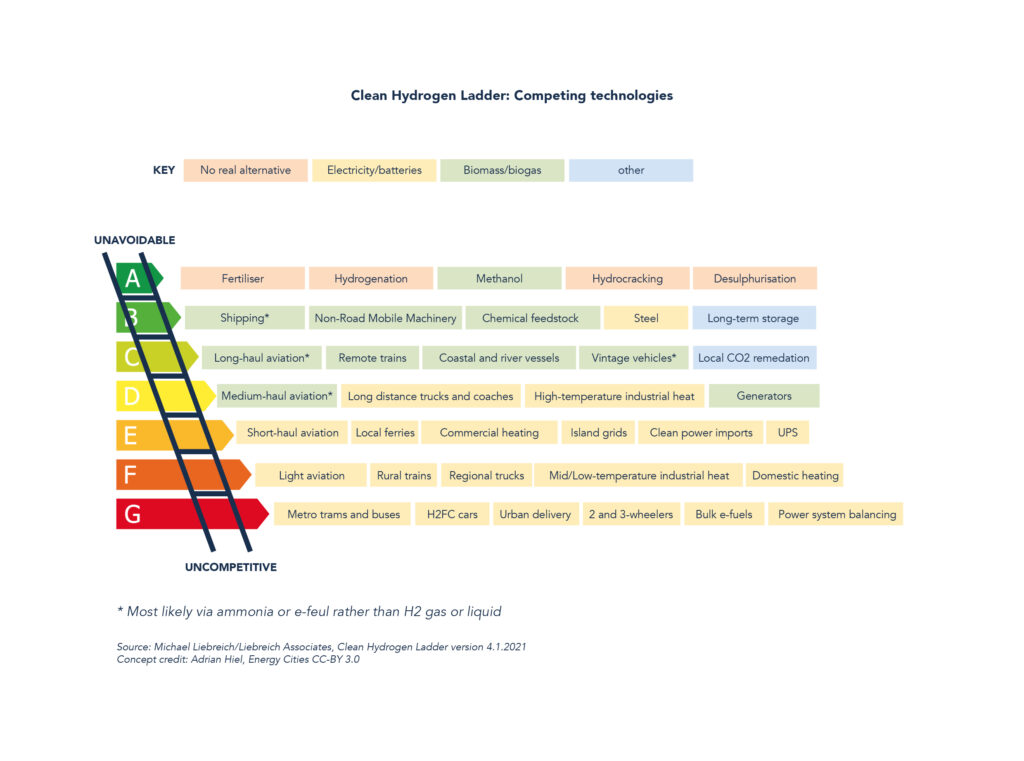

This means that choices will have to be made. Choices between applications that simply cannot be decarbonised without green hydrogen, and applications for which sustainable alternatives do exist. An example from the first category is the steel sector, which currently uses coal as a feedstock to reduce iron ore. Hydrogen could do the same job, without CO2-emissions, . An example from the second category is the (light) transport sector and the heating of buildings. Batteries and heat pumps, both powered by electricity, are much more efficient from an energy point of view for powering light vehicles and heating buildings, respectively. As such, it is not that hydrogen can be used for just about anything that that will actually be the case. On the contrary, while some applications of green hydrogen are unavoidable, others should be avoided. The British energy specialist Michael Liebreich has summarised this in an easy-to-understand format in a “hydrogen ladder”. The ladder shows the most desirable applications of hydrogen at the top and the less desirable ones at the bottom. The diagram should be on the desk of every policymaker working with energy (and therefore hydrogen).

Imports from ‘hydrogen countries’

In recent years, the idea of a hydrogen economy has made a comeback (even though it never went away). Hydrogen was first mooted in the 1970s and 1980s in response to the oil crisis, then faded into the background, only to return to the fore at the turn of the millennium. Today, the idea – often accompanied by the catchphrase “when you burn hydrogen you only emit water” – is being mooted again. And today, this ‘hydrogen economy of the future’ is a worldwide phenomenon. Since sun and wind are scarce, especially in a small and often cloudy country like Belgium, ambitious plans are being rolled out to import green hydrogen from areas where renewable sources are abundant and there is also enough space to exploit them. These are countries such as Australia, Morocco, Chile, Namibia and, of course, the Gulf States. The green hydrogen would be produced in these countries in electrolysers and then distributed around the world in large tankers. As is the case today with oil and gas.

That all sounds very nice, but then the electricity mix in these ‘hydrogen countries’ has to be sufficiently green. And that is easier said than done, because it involves more than just connecting an electrolyser to a large solar or wind farm. Indeed, this approach does not green the power mix in the hydrogen-producing countries, and greenhouse gas emissions remain too high. So, first and foremost, this mix needs to be further decarbonised. Only when the emissions are low enough can it be used to produce low-carbon or green hydrogen. For this, energy experts use the limit value of 140 grams of CO2 per kilowatt-hour of electricity. This is more or less how carbon-intensive the current production of grey hydrogen is. In order to produce green hydrogen, the value for the power mix must therefore remain well below this level. This is quite a challenge, because in Europe it currently stands at 216 g/kWh. And even in the above-mentioned future hydrogen countries, it is still well above 140 h/kWh. Therefore, the best way to green the global economy is first to reduce greenhouse gas emissions from the power mix.

Flemish innovation in hydrogen technology

Meanwhile, the efficiency of the electrolysis process can be increased. Innovation in hydrogen technology is therefore certainly still desirable and even absolutely necessary. In this domain, our country is a hive of activity. For example, VITO/imec/EnergyVille has joined forces with several major Belgian companies to make the production of hydrogen via electrolysis more efficient. The aim is to increase efficiency from 70 to 80%. This is taking place within the HYVE project, in which a cost-efficient and sustainable technology platform is being developed for gigawatt-scale hydrogen production. Further, WaterstofNet aspires to increase knowledge sharing among its members and unites many parties that are active in relation to hydrogen.

Belgium, and Flanders in particular, are also ideally situated to play an important logistical role in the burgeoning global hydrogen economy. A study by the Hydrogen Import Coalition, in which not only the Flemish seaports but also governments and several major Belgian companies are working together, showed early last year that our region can be fairly ambitious in the international hydrogen market. As such, cooperation agreements have already been concluded with countries such as Oman, Namibia and Chile for the future import of green hydrogen from those countries to Flemish ports. In Oman, the Flemish company DEME is even involved in the development of a green hydrogen plant with a capacity of up to 500 megawatts. The plant should be operational by 2026. The Belgian company CMB, together with other companies from our country, is building a solar park in Namibia that will also be able to produce one million tonnes of green hydrogen locally from 2026 onwards.

For Flanders, green hydrogen offers superb economic opportunities and the actions taken in 2021 must therefore be built on in the coming years – preferably on a larger scale and faster. Indeed, without green hydrogen it will not be possible to achieve a sustainable global economy. In fact, there are no real alternatives to the decarbonisation of, for example, the steel and various chemical sectors – sectors that are, moreover, crucial to the Flemish economy. The dream of the hydrogen economy is therefore still very much alive. But the versatility of green hydrogen also has a downside. Because it can be used for so many applications, it will become a scarce commodity in the coming decades – no matter how much we produce. In other words, we need to handle it very wisely. This is the only way the dream will be realised.

Gerrit Jan Schaeffer, General Manager EnergyVille